Artificial Intelligence (AI) is no longer a peripheral experiment in manufacturing—it has become a strategic pillar for leading factories worldwide. From predictive maintenance to quality inspection, AI technologies are being integrated into core production processes, delivering measurable gains in efficiency, accuracy, and flexibility. This article explores several successful real-world AI applications in manufacturing and how they are fundamentally transforming the way goods are produced.

1. Predictive Maintenance: Reducing Downtime and Cost

One of the most impactful applications of AI in manufacturing is predictive maintenance. Rather than relying on scheduled inspections or reacting to equipment failures, AI-powered systems monitor machine health in real time and predict when components will fail—allowing for proactive intervention.

Case Example: Siemens

Siemens has implemented AI-based predictive maintenance in its gas turbine production. By analyzing sensor data across thousands of machines, their system identifies early signs of wear and potential failure. This not only reduces unplanned downtime but also extends equipment life and lowers maintenance costs.

Impact:

- Downtime reduced by 20–30%

- Maintenance cost savings of up to 15%

- Higher overall equipment effectiveness (OEE)

2. AI-Powered Quality Inspection: Enhancing Accuracy and Speed

Traditional visual inspection systems are limited in their ability to adapt to product variations or subtle defects. AI, particularly computer vision and deep learning, allows for dynamic, accurate, and scalable quality control processes.

Case Example: Landing AI & Foxconn

Landing AI collaborated with Foxconn, one of the world’s largest electronics manufacturers, to deploy machine vision systems for detecting microscopic defects in components. Unlike traditional systems, their AI models continuously learn and improve, even when defect examples are limited.

Impact:

- Inspection accuracy increased by over 90%

- Reduction in false positives and unnecessary rework

- Consistent inspection standards across global facilities

3. Supply Chain Optimization: Smarter Forecasting and Logistics

AI is being used to optimize manufacturing supply chains through better demand forecasting, inventory management, and logistics planning. These systems learn from historical data and real-time inputs (weather, geopolitics, market trends) to make accurate predictions and reduce risk.

Case Example: Bosch

Bosch uses AI to create intelligent supply chain networks. Their systems can forecast component demand across markets, identify supply risks early, and adjust procurement strategies automatically. This AI-driven approach has helped the company navigate disruptions such as the global semiconductor shortage.

Impact:

- Improved inventory turnover rates

- Reduced supply chain disruption time

- Higher customer fulfillment accuracy

4. Process Optimization and Energy Efficiency

AI can simulate and analyze manufacturing processes to identify inefficiencies and optimize production parameters. This is especially valuable in energy-intensive industries such as steel, chemicals, and automotive.

Case Example: General Electric (GE) – Digital Twin Technology

GE uses AI-enabled digital twins—virtual replicas of physical assets—to simulate production lines and optimize operations in real time. At one of its manufacturing plants, GE reduced energy consumption by simulating thousands of process scenarios using AI.

Impact:

- Up to 10% energy savings

- Reduced process variability

- Faster time-to-market for product iterations

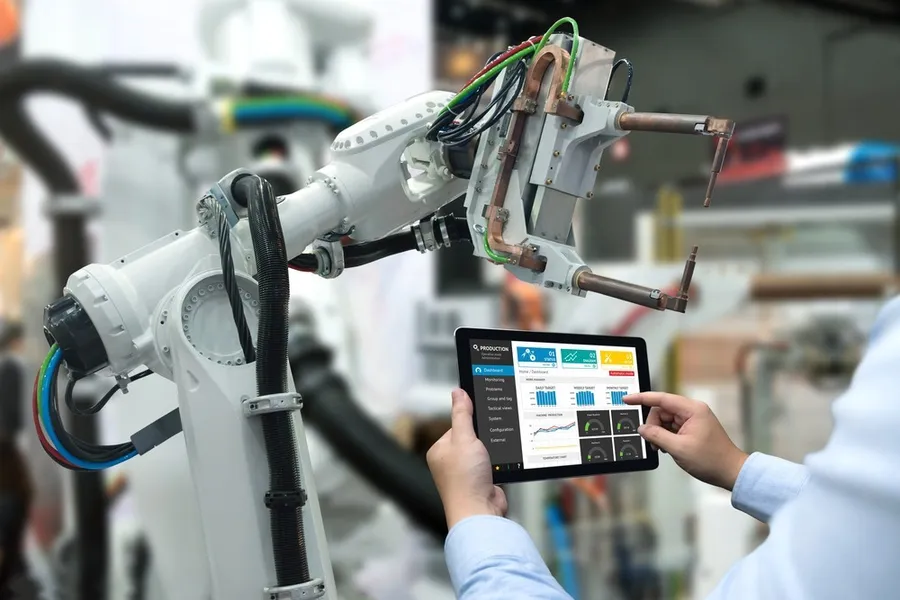

5. Robotics and Autonomous Systems in Smart Factories

Robots have long been used in manufacturing, but AI now allows them to operate more flexibly and collaboratively. These smart robots can adapt to changing environments, work safely alongside humans, and learn tasks without hard programming.

Case Example: BMW Group

BMW uses AI-powered robots to assist with assembly tasks in its Munich and Spartanburg plants. The robots collaborate with human workers in final assembly, using AI to detect and adjust to human movements, part variations, and assembly conditions.

Impact:

- Increased throughput in final assembly lines

- Enhanced worker safety and ergonomics

- Faster changeover and product customization

6. Mass Customization Through AI

Consumers are demanding more customization, and AI is enabling manufacturers to deliver tailored products without sacrificing efficiency. AI systems analyze customer data and production capabilities in real time to dynamically adjust production.

Case Example: Adidas – Speedfactory

Adidas’s now-retired “Speedfactory” project used AI-driven automation and robotics to produce customized footwear at high speed. The initiative showed that AI can drastically reduce design-to-shelf cycles and enable near-shore production.

Impact:

- Shoe production lead time reduced by 66%

- Increased capacity for small-batch, on-demand manufacturing

- Valuable lessons for integrating AI in product personalization

7. Natural Language Processing for Workflow Automation

AI is also being used to automate communication within manufacturing processes. NLP systems can interpret maintenance reports, process documentation, and operator feedback to identify systemic issues or optimize workflows.

Case Example: Honeywell

Honeywell uses AI-driven knowledge management systems that analyze technicians’ notes, service tickets, and manuals. The system suggests solutions to problems or routes them to the appropriate experts, shortening downtime and improving knowledge sharing.

Impact:

- Faster resolution of technical issues

- Enhanced operational learning across global teams

- Improved consistency in problem diagnosis

Key Lessons from These Use Cases

The most successful AI applications in manufacturing share several common factors:

- Integration with existing systems: AI doesn’t work in isolation—it thrives when integrated with ERP, MES, and IoT infrastructure.

- Real-time data availability: High-quality, real-time sensor and operations data are essential for effective AI performance.

- Human-AI collaboration: AI augments—not replaces—human expertise, particularly in complex decision-making.

- Scalability and adaptability: The best AI solutions are flexible enough to learn from new inputs and scale across sites.

Challenges to Address

While the potential of AI in manufacturing is vast, several challenges must be addressed:

- Data silos: Many factories lack centralized, clean, and standardized data across departments.

- Change management: Workforce resistance and lack of digital skills can hinder adoption.

- Cybersecurity risks: Connecting AI and IoT introduces new vulnerabilities in production environments.

- Ethical concerns: As AI makes more decisions, governance around transparency and accountability is critical.

Conclusion: A New Era of Intelligent Manufacturing

The manufacturing industry is entering a new era, where AI plays a central role in improving efficiency, agility, and innovation. The use cases outlined above prove that AI is not just about automation—it’s about transformational intelligence, enabling manufacturers to produce smarter, faster, and more sustainably.

As more companies adopt AI at scale, the competitive advantage will no longer lie in access to technology alone—but in how intelligently it is implemented and integrated into operations. For forward-thinking manufacturers, AI is not just a tool—it is a strategic asset reshaping the future of production.