Introduction

The manufacturing sector is undergoing a profound transformation with the advent of artificial intelligence (AI) technologies. AI is no longer a futuristic concept; it is a powerful tool that is being integrated into factories, supply chains, and production lines worldwide. As industries face increasing pressure to improve productivity, reduce costs, and innovate, AI offers transformative capabilities that optimize operations and unlock new possibilities in manufacturing.

AI is revolutionizing key aspects of manufacturing—from predictive maintenance and process optimization to smart automation and quality control. This article explores the critical role of AI in manufacturing, how it is reshaping the industry, and the challenges and opportunities it presents for businesses seeking to implement AI-driven solutions.

1. The Role of AI in Modern Manufacturing

AI’s application in manufacturing is broad, spanning numerous functions that contribute to efficiency, safety, and quality. As AI technologies become more sophisticated, their integration into manufacturing processes has proven to be a game-changer.

1.1 Predictive Maintenance

One of the most significant ways AI is revolutionizing manufacturing is through predictive maintenance. Traditionally, manufacturing companies have relied on scheduled maintenance or reactive repairs when equipment breaks down. However, these methods are often inefficient and costly. AI-powered predictive maintenance uses machine learning algorithms to analyze data from sensors embedded in machinery. By monitoring equipment health in real-time, AI can predict when a machine is likely to fail and recommend proactive maintenance before problems occur.

- Benefits: Predictive maintenance helps manufacturers avoid costly downtime, reduce repair expenses, and increase the overall lifespan of machinery.

- Example: Companies like General Electric and Siemens are already using AI to monitor the condition of their industrial equipment, minimizing failures and improving production efficiency.

Predictive maintenance is transforming asset management in manufacturing by shifting the approach from time-based maintenance to condition-based maintenance, which is much more efficient and cost-effective.

1.2 Process Optimization and Quality Control

AI algorithms can also be used to optimize manufacturing processes, ensuring that each step of the production line is as efficient as possible. In process optimization, AI analyzes historical data, real-time inputs, and performance metrics to fine-tune production parameters such as temperature, pressure, and speed to maximize output and minimize waste.

In the realm of quality control, AI plays a vital role in improving product consistency and minimizing defects. Traditional quality inspection methods often rely on human workers, which can be prone to fatigue, error, or bias. AI, particularly in the form of computer vision, can analyze products at high speed and with incredible accuracy to detect defects or inconsistencies that may be missed by human inspectors.

- Benefits: AI-driven quality control systems can detect minute defects, optimize material use, and ensure higher consistency, leading to superior product quality and fewer returns or rework.

By utilizing real-time data and machine learning, AI helps manufacturers continuously improve production quality, reduce scrap, and enhance the overall effectiveness of the production line.

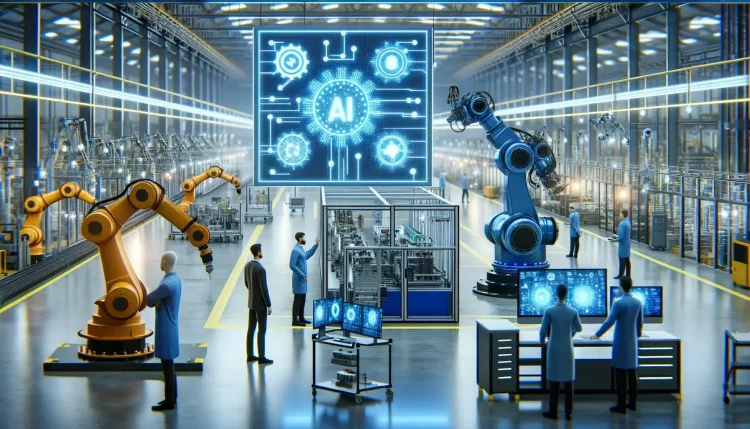

1.3 Smart Factories and Automation

The vision of the smart factory has long been the ultimate goal for manufacturers looking to fully leverage AI. Smart factories are equipped with interconnected machines, devices, and systems that communicate with each other in real-time, creating a highly automated and intelligent production environment.

AI enables greater levels of automation in manufacturing processes by replacing manual labor with robots and intelligent machines. These robots can perform repetitive, hazardous, or precise tasks with high efficiency and little human intervention. Additionally, AI allows machines to learn and adapt to changes in the production environment, improving their performance over time.

- Example: Tesla’s factory in Fremont, California, integrates AI-powered robots in their production line, enabling rapid assembly and high levels of customization with minimal human intervention.

In a smart factory, AI can monitor and control the entire production process, adjusting workflows, ensuring proper inventory management, and optimizing supply chains.

1.4 Supply Chain Optimization

AI also plays a crucial role in the optimization of supply chains, an area of manufacturing that directly impacts both cost efficiency and customer satisfaction. By using AI to analyze vast amounts of data—from supplier lead times to demand forecasting—manufacturers can optimize their supply chains to ensure timely production and delivery of goods.

- AI Applications: AI algorithms can predict demand more accurately, improve inventory management, and recommend optimal order quantities and shipment routes. This reduces the risk of overstocking or stockouts, minimizes shipping costs, and improves customer satisfaction.

- Example: Companies like Amazon and Toyota use AI-powered supply chain optimization tools to streamline their logistics and ensure the efficient movement of goods.

Supply chain management has become a key area where AI contributes not only to cost savings but also to improving customer service by ensuring that products are delivered on time and in the right quantities.

2. The Advantages of Implementing AI in Manufacturing

AI offers numerous advantages for manufacturers who choose to adopt and integrate it into their operations. These benefits can be realized across various areas, including operational efficiency, cost savings, and increased competitiveness.

2.1 Increased Efficiency and Productivity

AI technologies enhance productivity by automating repetitive and time-consuming tasks, enabling workers to focus on higher-value activities. AI systems can analyze data in real time, allowing manufacturers to optimize production processes, monitor equipment performance, and adjust parameters for maximum efficiency.

- Example: AI-driven robots are used in factories to assemble products, package goods, and perform quality control, significantly reducing the time needed for manual labor.

The increased automation enabled by AI means that factories can produce more goods in less time, improving overall productivity and reducing production costs.

2.2 Cost Reduction and Resource Optimization

By using AI to predict maintenance needs, manufacturers can reduce the likelihood of costly downtime caused by equipment failures. AI also helps optimize resource allocation by analyzing production data and determining the most efficient use of materials, machinery, and labor.

- Example: In industries such as steel production, AI can optimize energy consumption, reduce waste, and lower emissions, resulting in cost savings and a smaller environmental footprint.

AI also allows manufacturers to optimize inventory management, reducing the need for large stockpiles and lowering warehousing costs. This improves cash flow and ensures that capital is used more efficiently.

2.3 Enhanced Safety and Risk Management

Manufacturing environments are often dangerous, with workers exposed to heavy machinery, hazardous materials, and complex operations. AI can help improve safety by monitoring work environments and detecting potential risks before they lead to accidents.

- Example: AI-powered safety systems can monitor worker movements, detect safety hazards, and alert operators about equipment malfunctions that may cause accidents or harm.

Moreover, AI-driven systems can identify risks in production processes and recommend corrective actions to prevent accidents, making workplaces safer for employees.

2.4 Customization and Flexibility

AI offers manufacturers the ability to produce customized products in a cost-effective manner. With the help of AI, companies can use flexible production lines that adjust in real-time to meet customer demand, enabling mass customization.

- Example: Companies like Nike have integrated AI into their manufacturing process to produce personalized sneakers based on individual customer preferences, without sacrificing speed or cost-effectiveness.

As consumer preferences increasingly shift toward personalized products, AI enables manufacturers to respond quickly and efficiently to changing market demands.

3. Challenges in Implementing AI in Manufacturing

While AI holds immense potential for transforming manufacturing, its implementation is not without challenges. Manufacturers face several obstacles when adopting AI, including technical, organizational, and financial barriers.

3.1 Data Quality and Availability

AI relies on data to function, and for AI models to work effectively, they need access to high-quality, accurate, and abundant data. However, many manufacturers struggle with fragmented, inconsistent, or incomplete data, which can undermine the effectiveness of AI applications.

- Challenge: Ensuring that data is collected from various sources, standardized, and structured in a way that AI algorithms can process is a significant hurdle for many manufacturers.

Addressing these data-related issues requires investments in data infrastructure, sensor technology, and data governance practices to ensure the accuracy and consistency of data flowing through AI systems.

3.2 High Initial Costs and ROI Uncertainty

The initial investment in AI technologies can be high, especially for small and medium-sized enterprises (SMEs) in manufacturing. From purchasing AI software to upgrading machinery and training employees, the upfront costs can be significant.

- Challenge: Manufacturers must carefully evaluate the potential return on investment (ROI) of AI systems, taking into account long-term benefits such as reduced maintenance costs, improved productivity, and enhanced product quality.

In many cases, the financial outlay for AI integration may not produce immediate results, which can deter some businesses from adopting the technology.

3.3 Workforce Adaptation and Skills Gap

The widespread adoption of AI also requires a shift in the workforce. AI and automation systems can replace certain manual tasks, but they also require highly skilled workers to operate, maintain, and optimize these technologies. Ensuring that employees have the necessary skills to work with AI systems is crucial.

- Challenge: Manufacturers may struggle to find workers with the expertise needed to manage and troubleshoot AI systems, leading to a skills gap.

To overcome this challenge, companies must invest in training and development programs to upskill their workforce and foster a culture of collaboration between human workers and AI-powered machines.

4. The Future of AI in Manufacturing

As AI technology continues to evolve, its applications in manufacturing will become even more advanced and widespread. Several key trends indicate where the industry is headed:

- Edge AI: With the increasing use of edge computing, AI algorithms will be deployed directly on factory floors, enabling faster decision-making and real-time optimization without the need for cloud connectivity.

- Collaborative Robotics (Cobots): AI-powered robots will work alongside human workers, enhancing productivity and safety by performing tasks that complement human abilities.

- AI-Driven Sustainability: AI will continue to help manufacturers reduce waste, optimize energy use, and lower emissions, driving the industry’s push toward sustainability.

- Autonomous Supply Chains: AI will enable the development of fully autonomous supply chains, from demand forecasting to delivery, making manufacturing operations more efficient and responsive.

Conclusion

AI is not just a passing trend in the manufacturing industry; it is a transformative technology that is reshaping how products are designed, produced, and delivered. By embracing AI, manufacturers can improve efficiency, reduce costs, enhance product quality, and adapt to changing market demands. However, realizing the full potential of AI requires overcoming technical, financial, and organizational challenges, as well as a commitment to investing in data, infrastructure, and workforce skills.

The future of manufacturing is undeniably intertwined with the development and implementation of AI. By harnessing the power of AI, manufacturers can position themselves for long-term success in an increasingly competitive and technology-driven global market.