Introduction

The logistics industry is one of the most essential sectors in global trade and commerce. However, as consumer expectations increase and global supply chains become more complex, traditional logistics methods are often too slow, inefficient, and costly. This is where Artificial Intelligence (AI) and automation come into play.

By leveraging cutting-edge technologies like machine learning, robotics, and predictive analytics, companies in the logistics sector are achieving a paradigm shift—redefining how goods are transported, stored, and delivered. AI-driven logistics solutions are making the entire supply chain faster, more cost-effective, and responsive to real-time demands.

In this article, we will explore how AI and automation are transforming the logistics industry, with real-world examples from leading companies that have embraced these technologies. These innovations are not only improving operational efficiency but are also reshaping customer experiences and creating new business models.

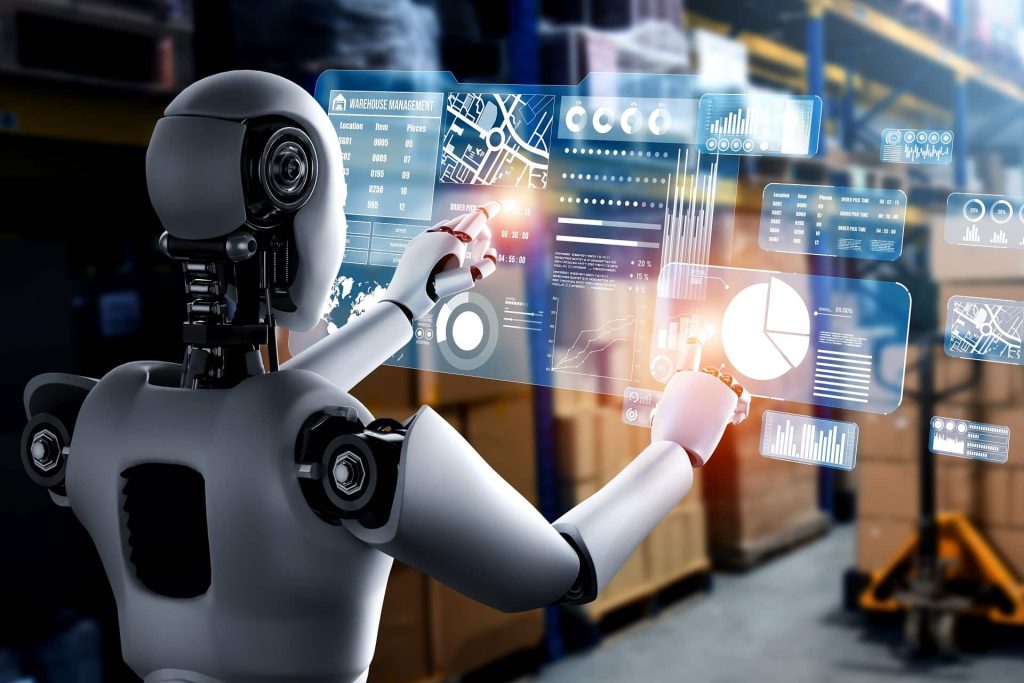

1. AI in Warehouse Automation: Revolutionizing Inventory Management

1.1 AI and Robotics for Efficient Warehouse Operations

Warehouses have traditionally been labor-intensive environments, requiring extensive human resources for sorting, storing, and retrieving goods. However, AI-driven automation is transforming these operations, dramatically improving the speed and accuracy of warehouse tasks.

Case Study: Amazon and Its AI-Powered Robotics

- Challenge: Amazon operates some of the largest and most complex warehouses in the world, handling millions of products. Traditional manual systems were often inefficient and prone to errors, resulting in delays and increased operational costs.

- AI Solution: Amazon has integrated AI-powered robots into its fulfillment centers to automate key warehouse functions. The company uses Kiva robots—small autonomous robots that move goods to human workers for packaging. Additionally, Amazon employs machine learning algorithms to optimize inventory management, predict demand, and improve the organization of goods.

- Outcome: Amazon reports that these AI-driven robots have helped increase warehouse efficiency by up to 30%, reducing the time required to process orders and lowering operational costs. This technology also contributes to better inventory management, helping Amazon meet the ever-growing demand for fast delivery.

Other Examples:

- Ocado: Ocado, a UK-based online grocery retailer, uses AI-powered robots and machine learning in its warehouses to manage inventory and pick products with remarkable speed and accuracy. The company has automated its entire supply chain, enabling faster and more accurate deliveries.

- XPO Logistics: XPO Logistics has introduced AI-driven robots in its warehouses to perform tasks such as sorting, order picking, and packaging. This has led to improvements in order accuracy and processing speed.

2. AI in Predictive Logistics: Enhancing Supply Chain Efficiency

2.1 AI-Driven Predictive Analytics: Optimizing Delivery Routes and Schedules

AI’s ability to process massive amounts of data in real-time allows logistics companies to make highly accurate predictions about delivery times, traffic conditions, and even customer demand. Predictive logistics uses AI algorithms to analyze historical data and make recommendations for optimizing transportation routes, managing inventory, and improving overall supply chain efficiency.

Case Study: DHL’s Use of AI for Predictive Logistics

- Challenge: DHL needed to improve the efficiency and predictability of its global logistics network, which involves the movement of goods across various geographies with varying levels of demand and transportation constraints.

- AI Solution: DHL uses AI-powered predictive analytics to forecast delivery times, optimize routes, and anticipate potential disruptions in the supply chain. By analyzing historical data, weather patterns, and traffic conditions, the system provides real-time updates and recommendations for adjusting delivery routes and schedules.

- Outcome: DHL has significantly reduced delivery delays and improved overall efficiency, with some reports indicating a 10% reduction in fuel consumption and a 15% increase in delivery speed. The AI-powered system also provides greater visibility into potential risks, allowing DHL to proactively mitigate disruptions.

Other Notable Predictive Logistics Examples:

- UPS: UPS utilizes ORION (On-Road Integrated Optimization and Navigation), an AI-driven tool that optimizes delivery routes for its fleet, saving millions of gallons of fuel annually and improving delivery efficiency.

- FedEx: FedEx employs AI-powered algorithms to predict package demand and adjust its logistics networks to meet customer needs more efficiently, leading to improved supply chain agility and reduced operational costs.

3. AI in Last-Mile Delivery: Redefining Customer Experience

3.1 AI and Autonomous Vehicles: The Future of Last-Mile Delivery

The last mile of the delivery process—the final leg of transportation from the distribution center to the customer’s doorstep—is one of the most critical and expensive aspects of logistics. Companies are increasingly turning to AI-powered autonomous vehicles to tackle last-mile delivery challenges, reducing costs and speeding up delivery times.

Case Study: Nuro’s Autonomous Delivery Vehicles

- Challenge: Traditional last-mile delivery can be costly due to factors like traffic congestion, labor costs, and vehicle maintenance.

- AI Solution: Nuro, an autonomous vehicle company, has developed self-driving vehicles specifically designed for last-mile delivery. These electric vehicles use AI to navigate streets safely and efficiently while delivering goods directly to customers’ homes.

- Outcome: Nuro’s autonomous vehicles have reduced delivery costs by up to 40% compared to traditional delivery methods. The company has partnered with various retailers, including Domino’s and Walmart, to offer contactless, efficient last-mile delivery options.

Other Last-Mile Delivery Innovations:

- Starship Technologies: Starship Technologies uses AI-powered autonomous delivery robots to deliver food and small packages. These robots navigate sidewalks and urban environments to provide quick and cost-effective delivery solutions.

- Wing (by Alphabet): Wing, a subsidiary of Alphabet (Google’s parent company), utilizes drone delivery systems to provide ultra-fast deliveries of small goods. AI is used to optimize flight paths and ensure safety during delivery.

4. AI and Automation in Freight Management: Streamlining Operations

4.1 AI in Freight Transportation: Enhancing Load Optimization and Freight Matching

In freight transportation, one of the key challenges is maximizing the utilization of available space in trucks, ships, and planes. AI-driven systems are helping logistics companies optimize freight loads, match available carriers with shippers, and reduce costs.

Case Study: Loadsmart and AI for Freight Matching

- Challenge: Traditional freight matching often leads to inefficiencies, such as empty trucks or suboptimal routing.

- AI Solution: Loadsmart, a logistics technology company, uses AI to match freight shipments with available carriers in real-time. The AI platform analyzes factors such as route efficiency, capacity availability, and carrier pricing to optimize freight transportation.

- Outcome: Loadsmart’s AI-driven system has significantly reduced transportation costs by increasing load utilization rates and improving freight matching accuracy, resulting in faster delivery and reduced carbon emissions.

Other Freight Optimization Examples:

- Convoy: Convoy uses AI to connect shippers with truck drivers in real-time, improving efficiency by minimizing empty miles and reducing operational costs.

- C.H. Robinson: C.H. Robinson uses machine learning algorithms to optimize freight routing, improve pricing accuracy, and enhance operational efficiency across its supply chain network.

5. The Future of AI in Logistics: Emerging Technologies and Trends

As AI continues to evolve, the potential applications in logistics are vast. The future of AI in logistics will likely include:

- Autonomous Drones and Vehicles: The continued development of autonomous drones and vehicles for last-mile delivery will revolutionize how goods are delivered, offering faster, more efficient, and cost-effective solutions.

- Blockchain Integration: The combination of AI and blockchain will help enhance transparency, traceability, and security in the supply chain, ensuring the integrity of goods from origin to destination.

- AI-Driven Smart Contracts: Logistics companies are exploring the use of AI and blockchain to create self-executing contracts that can automatically trigger actions (e.g., payments, shipment tracking) based on predefined conditions.

- 3D Printing and AI: The integration of 3D printing and AI will enable on-demand production of goods closer to the consumer, reducing the need for long-distance shipping and further optimizing supply chain efficiency.

Conclusion

AI and automation are transforming the logistics industry, enabling companies to achieve unprecedented levels of efficiency, speed, and cost-effectiveness. From warehouse automation to predictive logistics and autonomous delivery, these technologies are helping businesses meet the growing demands of the global marketplace.

As exemplified by companies like Amazon, DHL, and Nuro, the integration of AI and automation is driving logistics innovation. The future holds even greater potential, with emerging technologies like autonomous vehicles, AI-powered supply chains, and smart contract systems poised to take logistics to the next level.

For companies willing to embrace these changes, AI offers an opportunity to not only enhance operational efficiency but also create a more sustainable, cost-effective, and customer-centric logistics ecosystem.